Wood Texture Surface Treatments

Along the wood grain, gently feel the vitality of each mark of different depths. Take a deep breath, and imagine what the wood has been through. It might have grown up energetically in a place where the warm sun was shining upon. It might have grown up in a freezing place, standing up strong during every cold night. The changes of the four seasons become the nutrients that nourish the land, which eventually become pieces of wood panels that displays the beauty of nature. The required processes of restoring the natural appearance have become the professional assessment.

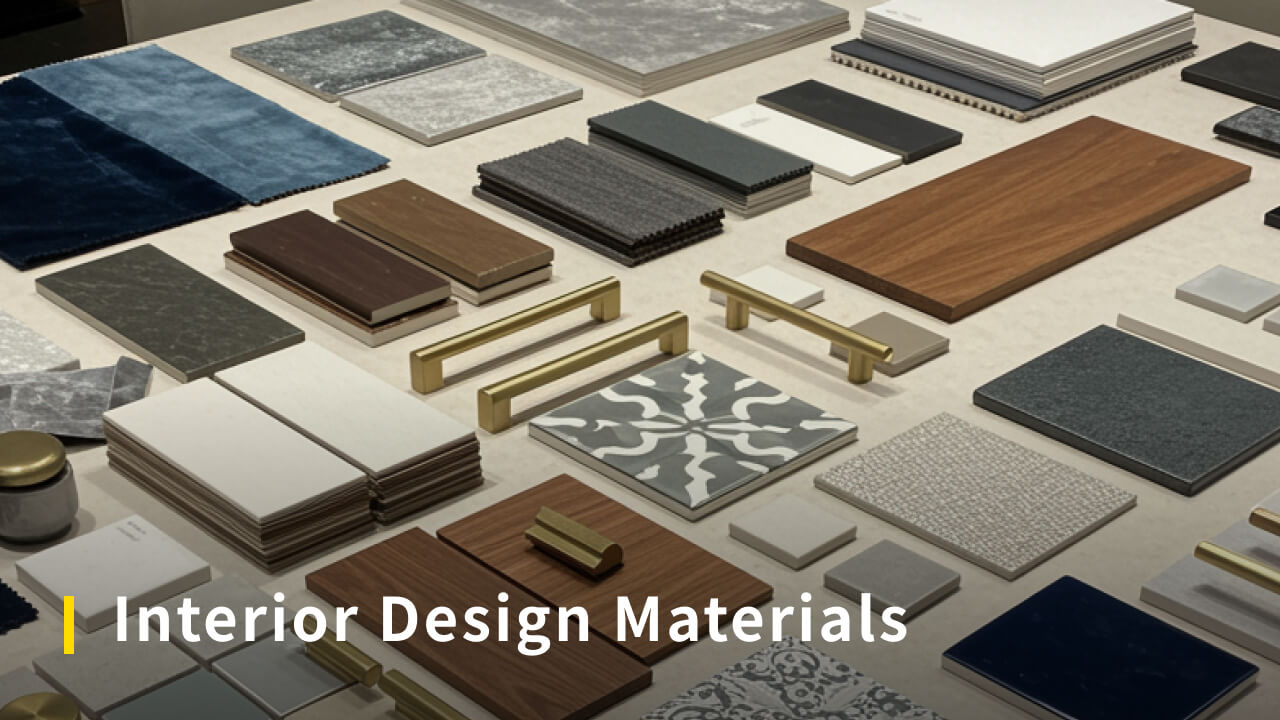

Comparison of Surface treatments: Flat / Open Pore / Wire Brushed (Image Credit: Keding Enterprises.)

Flat Finish: A Smooth and Flawless Finish that Comes with a Natural Luster

Flat treated panels come with an extremely smooth finish without any pores or kernels to be seen. It used to be the mainstream for real wood furniture. To create a flawless and smooth finish, the procedures the panel has to go through are very complex. Not only it has a high quality standard for the raw materials, the required precision and quality of the slicing, gluing, and lacquering procedures are also extremely demanding. Maple, come with tiny pores, which makes them suitable to be used as a material for flat finishes. The final product would come with a flat and smooth finish, while displaying a natural luster.

Flat Finish (Image Credit: Ming Dynasty design / K6101AN)

Open Pore Finish: Preserving the Natural Texture and Warmth while Displaying the Authenticity of Wood

Along with the interior design trends leaning towards natural styles. An increased amount of house owners tends to preserve the original beauty of natural materials, and starts to prefer the look of wood panels with a natural texture. To move away from the overly flawless finish of the flat surfaces that loses the uniqueness and vitality of natural wood, Keding developed an open pore surface treatment that preserves the pores, textures, and beauty of natural wood. The challenge of open pore finishes is to perfectly cover the pores with the coating. The coating has to protect each pore while preserving the texture and look. Keding has achieved both by our perseverance in quality and years of development. We have been constantly setting higher standards and pushing the quality and technology of wood products to the limits.

Wire Brushed Finish: Carving Various Depths of Natural Shading

Along the wood grain, gently feel the vitality of each mark of different depths. The natural warmth and textures of wood will bring the home owners back to a pure and authentic lifestyle. Wire brushed finishes are created by a wire brushing wheel that runs across the veneer surface, which carves numerous marks with various depths. The process recreates the texture of tree barks. The carving marks also follow the wood grain on the veneer, which drastically increase the realism.

Wire Brushed Finish (Image Credit: Wei Kong Design / K6110AN)

Conclusion

Keding has been dedicated to discovering different ways to display the beauty of wood. We not only offer a variety of tones and finishes, but also provide a wide selection of surface treatments including flat, open pore, wire brushed, rough cut, smoked, and gloss. Every type of surface treatment gives you a different sensory experience, while adding a different vibe on top of your interior space. Due to the difference of wood species and growing environment, the development of surface treatments requires immense research and testing. Our experience and persistence enabled us to create quality surface treatments and beautiful finishes!