The other label painting board with KD painting board differences

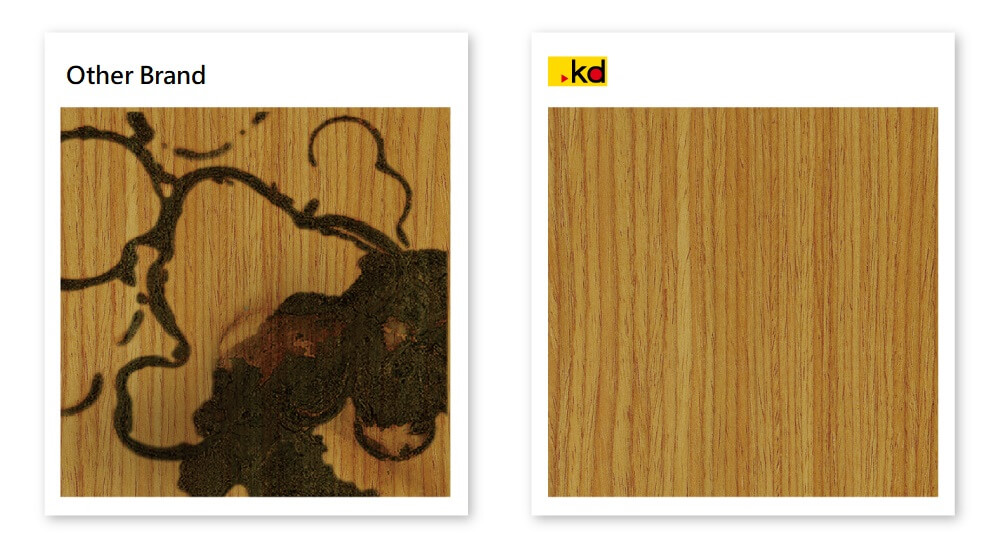

The comparison of thickness of light-colored veneer

other:Veneer that is overly thin allows the subrate’s texture and color to bleed through the veneer itself. Consequently, the color properties and texture of the veneer would be affected.

KD :Thick veneer does not only cover the surface of the substrate, it can also enhance the texture of the veneer.

Comparison of edge line coating on light-colored laminates

other:Other coating materials do not protect the edge line effectively. Often, due to the constant use, the edge line is contaminated, causing it to darken.

KD :The edge line is properly protected with our edge line coating, preserving its color for a long period of time.

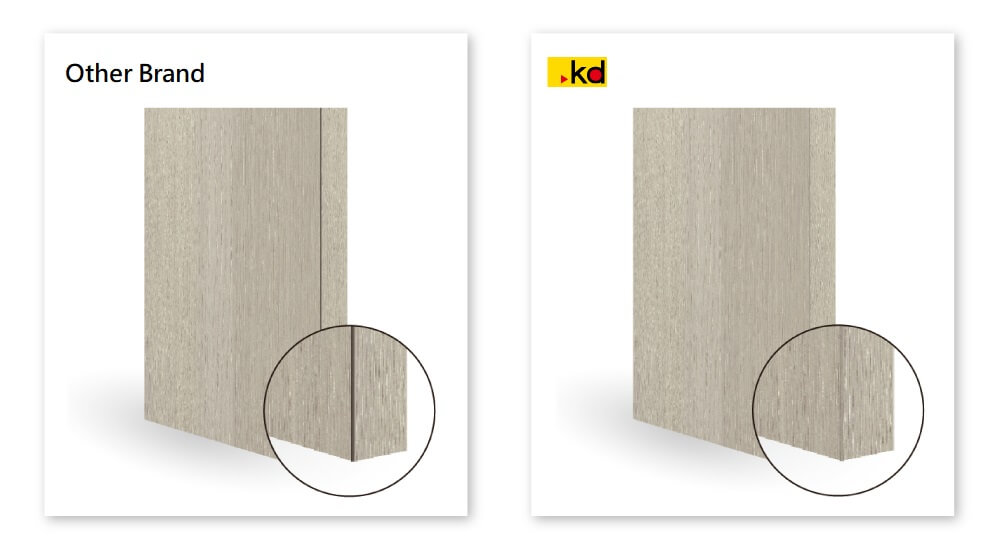

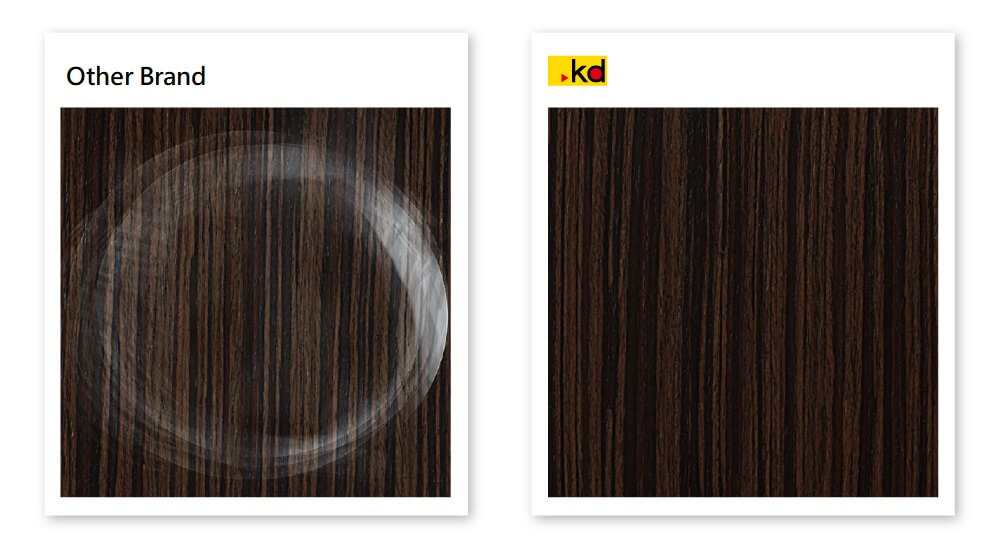

Comparison of edge line coating on the dark-colored laminates

other:Other coating materials do not protect the edge line effectively. Therefore, the veneer surface and the sides appear to be separate.

KD :The edge line is properly protected with our edge line coating, a combination between the veneer surface and the edge line create an appearance of one solid body.

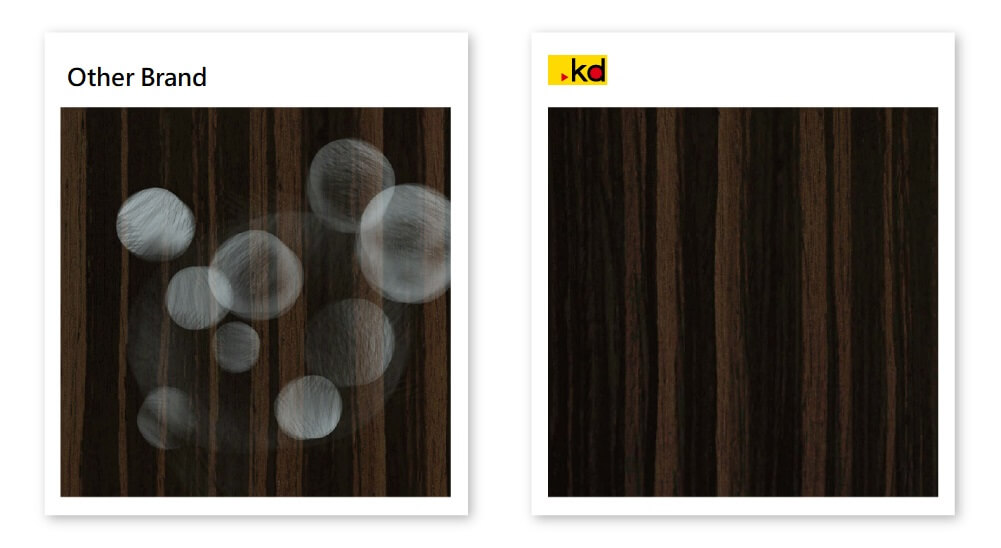

Humidity Durability

other:The open pore surface tends to contain dirt and darken due to the effects of humidity and everyday cleaning.

KD :Due to the proper coating of the surface, the open pore surface has no gaps. Therefore, the layers below the coating layer are not affected by humidity.

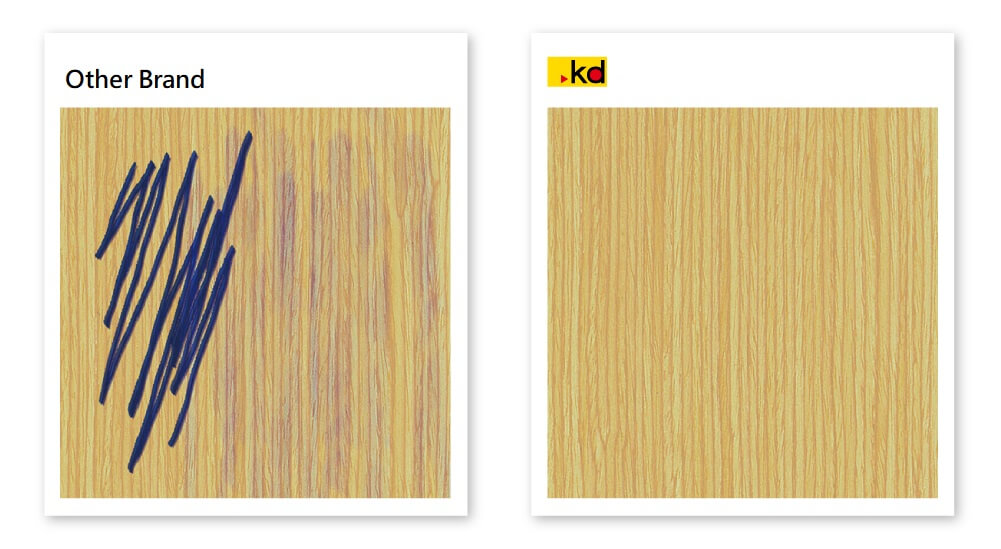

The marker contamination test

other:Due to the poor coating, after the surface is in contact with the ink, it is impossible to wipe off the remaining ink. After a period of use, the open pore surface also becomes contaminated, making the surface difficult to clean.

KD : The open pore surface of the wood is thoroughly coated. With a completely covered surface, ink is not able to pass through the coating, making the ink easy to wipe off.

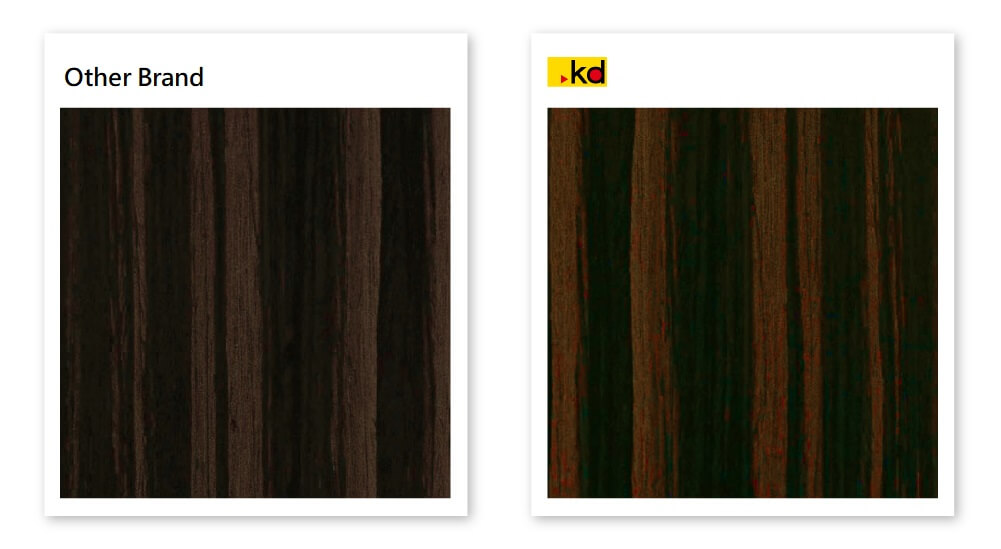

The 3-D comparison in coloring the veneer base and veneer surface

other:The surface layer is covered with excessive dyed coating which fogs the surface layer reducing the veneer’s natural 3-d texture.

KD :The optimal ratio for dyeing on surface layer to base layer is 70% to 30%. This proportion displays the veneer’s best 3-D texture.

Flame Retardancy

other:Traditional coatings have no flame retardant characteristics, which can also increase the scale of fire.。

KD :Every KD coated surface provides a protective flame retardant function.

Heat Resistance

other:The traditional coating surface is not resistant enough against the heat, blemishing of the surface occurs as a result.

KD :The toughness of the KD coated surface reaches the requirement to maintain the perfection of the surface while in contact with heated materials.

Chemical Solvent Resistance

other:Traditional coated surfaces are easily affected by chemical solvents which generate a blemishing situation.

KD :The KD surface provides chemical resistance which causes no change in appearance when exposed to chemical solvents.

Antibiotic Properties

other:Traditional coating can easily to boost the growth of germs under humid environment.

KD :KD coated surfaces can resist bacteria such as staphylococcus aureus and colon bacillus.

Humidity Resistance

other:Traditional painted surfaces tend to darken on the surface layer during the rainy seasons due to high amounts of humidity.

KD :KD coated surfaces can protect the wood veneer properly and is durable in ahumid environment.